Geoff Osborne leads us into this series with a success story that grew from farming roots but how many know, I wonder, that they have a world-class engineering company on their doorstep and that it was founded by a man who has been rightly described as one of Cornwall’s foremost inventors and innovators.

William Thomas (Tom) Teagle was born near St Columb in 1911 and at the age of two, the family moved to a 300 acre farm, Tywarnhayle, at Blackwater, rented from the Williams family. Tom’s formative years were at Blackwater Board School and later at a boarding school at Probus. Farming was in his blood and at the age of 15, he left school to help his father, Fred, on the farm. When Tom was just 19, Fred bought a farm back at St Columb and moved there with his wife, Eva, and three other children, leaving Tom to farm on his own at Tywarnhayle – a 19 year old boy running 300 acres! This was a reflection of the determination, nous and resourcefulness, which was to be his trademark for the next 60 years.

William Thomas (Tom) Teagle 1911 – 1989

William Thomas (Tom) Teagle 1911 – 1989

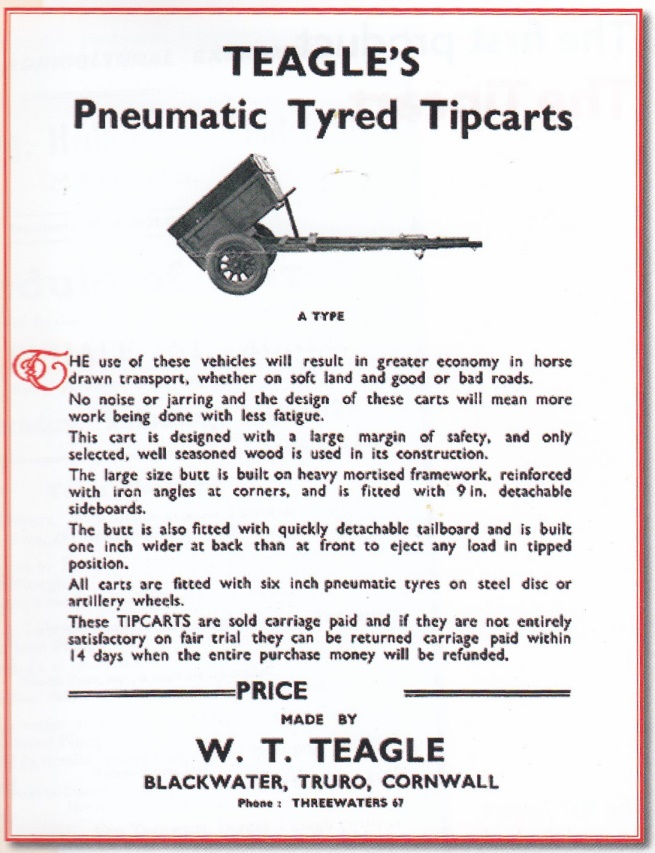

In 1937, at the age of 26, as a side-line to farming, he started manufacturing rubber-tyred tipcarts, initially using converted motor wheels then progressed onto new Dunlop wheels. His first sale to the retail trade was a Tipcart on converted motor wheels, invoiced on 3rd August, to E Mitchell & Son of Penzance for £13 0s 0d. Such was their popularity that Mitchell’s sold a further 6 Tipcarts in 1937. Tom realised that he had the beginnings of a business.

W T Teagle Tipcart Brochure

W T Teagle Tipcart Brochure

In 1939, Britain went to war and the call went out for food to feed the nation. At this point, Tom spotted a need for machinery to enable farmers to produce more food with the resources they had available to them. Initial pieces of equipment were basic by today’s standards, but at that time they were “state of the art” and in the country’s hour of need, they went up the road as fast as W T Teagle could produce them. In 1943, Tom’s vision of the future took things another step forward and a limited company, W T Teagle (Machinery) Ltd was formed.

Production continued, with demand outstripping what could be built. The business grew and Tom’s wife, Mary, looked after the commercial aspect whilst he concentrated on the engineering side of the company. New products, new designs, new ideas have always been what keeps a company vibrant and alive – W T Teagle(Machinery) Ltd certainly had all of those qualities. In post war years, when Britain was rebuilding itself, business was booming. For a while, farming ran quite happily alongside engineering but life got to the stage when there weren’t enough hours in the day, so something had to give – it was farming. Most of the 300 acres was sold off to neighbouring farmers whilst the farmstead, factory buildings and a few acres were retained, ultimately to grow into the modern manufacturing facility which we have today. In 2020, Teagle employs around 180 people, making it a major player in the local economy.

Teagle’s 2020 English Website Home Page

Teagle’s 2020 English Website Home Page

In the early days, potential customers beat a path to the door but times have changed: there is now fierce competition in the market place and Teagle has risen to meet that competition. There is now a field sales team of 12 people, seven in the UK and five overseas, with an administrative structure in the Blackwater office to support them all. Today, Teagle exports just over 50% of its turnover, shipping to over 50 countries worldwide.

Early products were functional, labour saving machines that were quite inventive in their time. Tom Teagle certainly had a flair for thinking outside the box and that was reflected in the popularity of Teagle’s products. Agricultural machinery has changed out of all recognition over the years. The quality has improved, the standard of finish has improved and the level of technology has advanced at a pace, all necessary to meet customer’s ever increasing expectations and their business needs. Teagle has grown its Product Engineering Department to keep its product range ahead of the pack. Today, its flagship product, the Tomahawk range of bale processors, are market leaders in the UK and form the mainstay of its turnover in the export market.

That’s a potted history of the company, so to speak, but lots of interesting things have happened along the way. Some happenings were serious – even damaging to the company, but most come under the heading of day to day steps in the development of a sound, thriving business organisation. There were also some others which, although they might not have been viewed so at the time, were much more light-hearted. In 2015, Tony Mansell and Fred Teagle got together to document some of the history leading up to Teagle’s 75 year anniversary and their excellent book, “Teagle, Reflections on 75+ years 1937 – 2015” makes very good reading. Copies are available from Teagle’s Sales Office at Blackwater or Waterstones in Truro – all of the proceeds go the Cornwall Hospice Care. Much reference has been made to their book in writing this article.

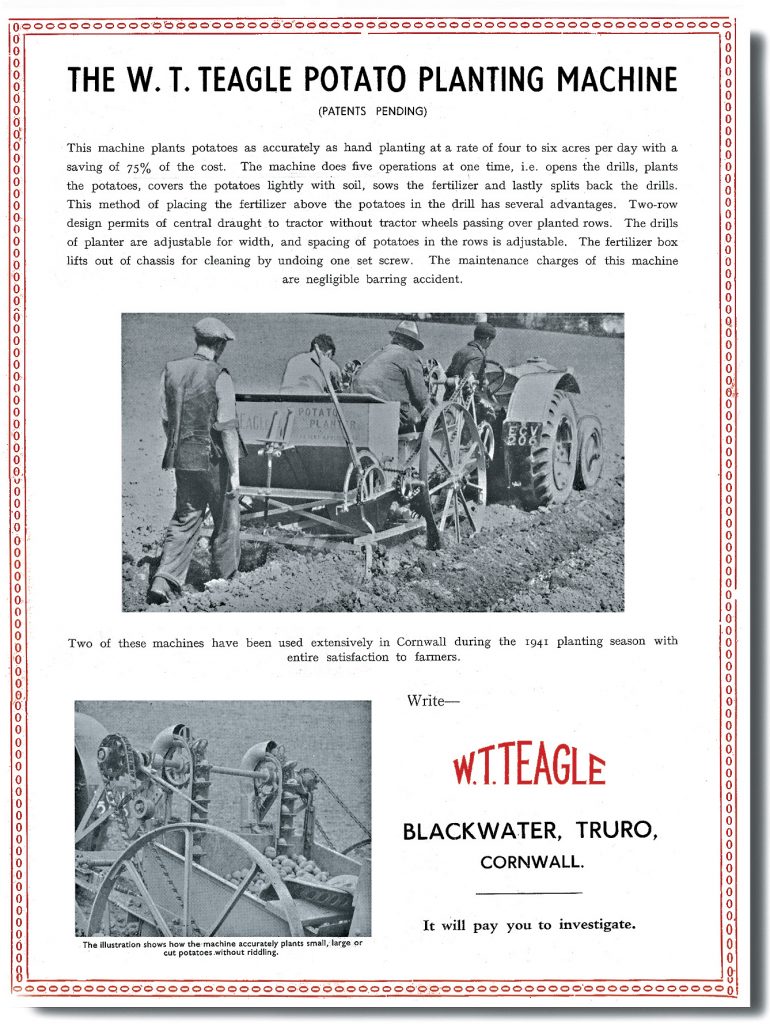

In the early stages of the second world war, Tom Teagle made a major contribution to “feeding the nation” by designing a novel automatic potato planter. Tom’s design not only planted potatoes, but also placed fertiliser adjacent to the seed so that a good crop was produced and a valuable resource used to best advantage. The machine was in such demand that the War Agricultural Executive Committee decided to support its manufacture. However, production had to be transferred to Dennings of Chard, who had a much larger factory facility than Teagle. It was agreed that W T Teagle would get a royalty on each machine sold, but that side of the deal was never honoured and Tom never forgot it. It would be a long time before he had anything made under licence again.

W T Teagle Potato Planter Brochure

W T Teagle Potato Planter Brochure

The Teagle Universal Planter in Action

The Teagle Universal Planter in Action

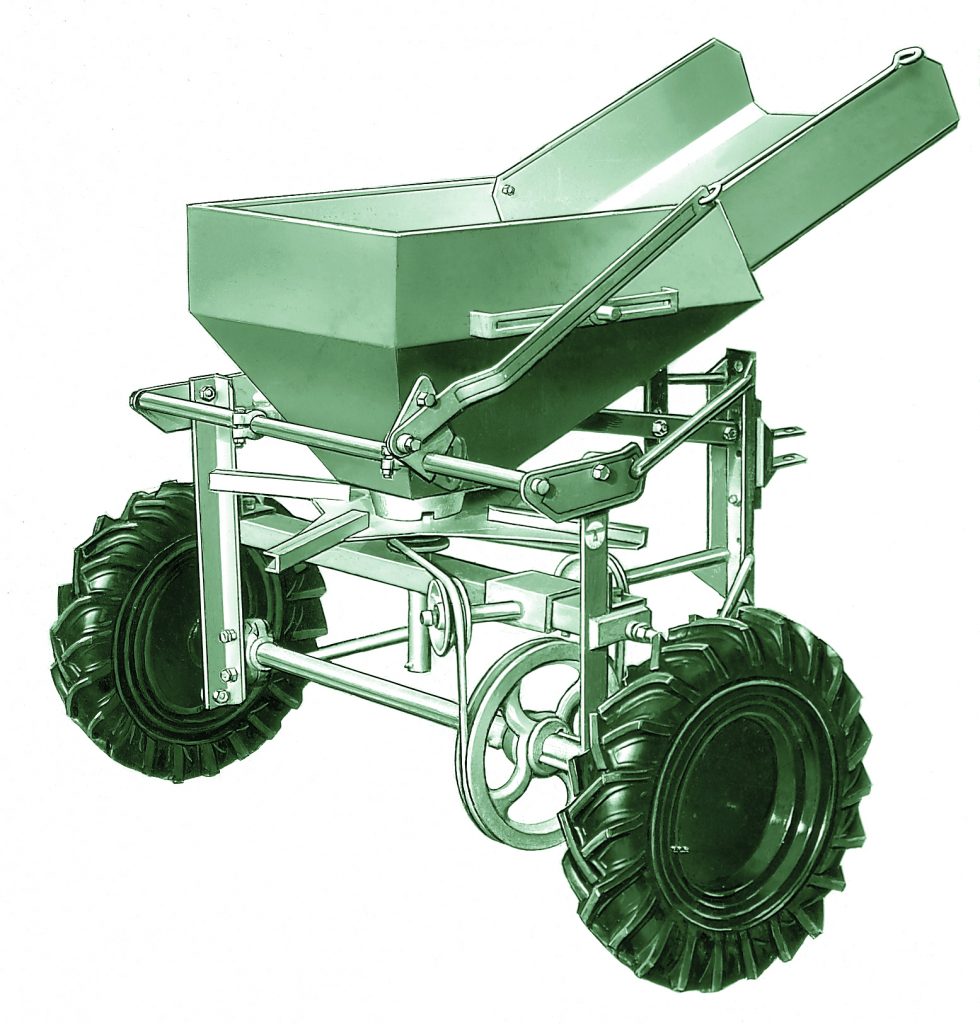

Again, as part of his efforts to help with the war effort, Tom designed a ‘Universal Planter’ This was at a time when virtually every farm in Cornwall grew some sort of planted row crop – be it potatoes, cauliflower or cabbages and Tom’s machine could handle all of them. Nearly every farm in Cornwall had a Teagle Universal Planter (and there are many still at the back of Cornish farm sheds today!

Many farm machinery manufacturers, either accidentally or intentionally, seem to focus their efforts on one particular product line for long periods of time. The company becomes synonymous with that type of machine in the market place. Teagle embarked on such a phase, starting in 1950, when the first trailed fertiliser spreader (broadcaster) was introduced. This machine was towed behind a trailer and fertiliser was shovelled into the machine by someone standing in the rear of the trailer. Health and Safety had not been invented at that stage! Over the years, some 14,000 trailed broadcasters were built, with very little competition in the market place. The situation changed when at one Smithfield Show in the mid 1950’s, 17 different machines appeared, all incorporating similar features.

The First Trailed Broadcaster

The First Trailed Broadcaster

By the late 1950’s nearly all tractors were fitted with Harry Ferguson’s 3-point linkage system and in 1957, Teagle launched what is claimed to be the world’s first mounted fertiliser spreader, driven by the tractor PTO drive.

The Versatile Mounted Broadcaster

The Versatile Mounted Broadcaster

The ‘Versatile’ broadcaster was launched at the 1960 Smithfield Show and within 3 years, production was running at 10,000 machines per year – a huge success. A major change came in 1971, when polyethylene hoppers replaced the earlier galvanised design. Yellow plastic hoppers, mounted in red steel frames, became the hallmark of Teagle fertiliser spreaders. In 2020, Teagle still manufactures broadcasters fitted with yellow plastic hoppers mounted in red steel frames, but the technology is very different.

The XT48 Mounted Broadcaster – 2020 Model

The XT48 Mounted Broadcaster – 2020 Model

In the early days, fertiliser came in 1 cwt. hessian sacks, was in powder form and was shovelled into the broadcaster from a trailer. Today, it comes in 600 kg plastic tote bags, is in granular form and is loaded into the machine from a tractor loader or materials handler. The driver sits in his cab, with the back window closed (listening to the radio) and controls the on/off shutter using the tractor hydraulic system.

A second product line, which the company became well known for, was the Titan range of tandem axle tipping trailers. The Titan was developed in response to the need for a large silage trailer, which was stable on hillsides and rode well over uneven ground. The Titan became a legend in the South West and over 4,000 were sold. Many are still in active service and bring good money at machinery sales.

The Teagle Toucan 8 Forage Wagon

The Teagle Toucan 8 Forage Wagon

In the early 1980s a product development occurred, which propelled Teagle into the farming headlines. It was theToucan Forage Wagon, which comprised a Teagle Titan trailer with a JF fine chop forage harvester built into the front of the chassis. The Toucan had a number of selling points, the first being that at the end of the silage season, the harvester unit could be removed, leaving a standard trailer which could be used for grain etc. for the rest of the year. The second and equally important feature was that it enabled one person to produce precision chopped grass and deliver it to the silage clamp. This system fitted well with many smaller father and son livestock farms in the UK at that time. The Toucan made headline news by winning several national machinery awards and really put Teagle Machinery back on the map.

The Toucan was good for Teagle in that it encouraged new thinking and new ways of operating as a business. Suddenly, the company was selling a product which operated in an environment where time was critical and service backup was important. There was nothing to focus a farmer’s mind more than a field of silage awaiting harvesting whilst the harvester was parked up awaiting a spare part. This all put the company in a good position to face the future in that there had to be an overnight delivery system for spare parts together with a dedicated Service Department to help and advise customers.

The biggest development of all also began in the early 1980s with the Lightning bale shredder. This machine chopped small bales of dry straw and discharged the shredded material from either side into cow cubicles for bedding purposes. The Lightning also found a market for bedding intensive poulty houses. At about this time, round bales were becoming popular as a way of storing straw, but there was very little by way of machinery to dispense the bales.

Teagle Lightning Small Bale Shredder

Teagle Lightning Small Bale Shredder

Round balers began to prove very successful as a way of conserving silage, first of all using enormous plastic bags and later using plastic wrapping machines. Teagle saw an opportunity here, first of all with a round bale shredder for delivering round bales of straw, chopped short into cubicles and later with a machine for shredding round bales of silage and dispensing it along feed barriers. The Teagle Tomahawk was born!

Tomahawk 8500 Bale Processor

Tomahawk 8500 Bale Processor

Over the years, the Tomahawk has become the company’s flagship product and has been very much the focus of the Design and Development team. The Tomahawk has been developed in response to the need for machines to handle big rectangular bales of straw, big rectangular bales of silage and also clamp silage. Today’s biggest Tomahawk, the C12 is capable of shredding up to 12 tons of dry straw per hour – a far cry from the Lightning, which would manage 250 kg per hour on a good day.

The Tomahawk C12 Processing Straw for Feed

The Tomahawk C12 Processing Straw for Feed

Today, the Tomahawk range is the market leader in the UK and forms the mainstay of the company’s export trade, with over half of production going abroad

To be viable, a company needs a full product range within any product line and also a broad enough selection of product lines to make it attractive to dealerships. There are some other machines in the Teagle range which make an important contribution to the success of the company.

Pasture Toppers and more recently Roller Mowers have been produced by Teagle since the mid 1970’s. Teagle Toppers come in a full range of sizes and configurations from the 4 ft, single rotor compact machine to the 9ft. front or rear mounted shaft drive unit.

The Teagle Topper 8 Offset Pasture Topper

The Teagle Topper 8 Offset Pasture Topper

The Teagle EKR/S Flail Mower Manufactured by Berti

The Teagle EKR/S Flail Mower Manufactured by Berti

To complement the Teagle manufactured rotary machines, a range of Italian manufactured Flail Mowers was added to the Teagle product line in about 2005. This meant that if a customer wanted a rotary Topper, Teagle could supply it and if he wanted a Flail Topper, Teagle also had the answer.

In 2010, Teagle started manufacturing rear discharge muck spreaders, initially with 10 and 12 ton models, but over the years, expanding downwards to 6 tons and upwards to 17 ton versions. It was felt that due to their heavy and robust construction, they just had to be branded as the Titan range. The Titan Trailer range had ceased production in 1995, so there was a gap in the name, long enough to be a break, but short enough to trigger memories. The top of the range Titan now incorporates weigh cells and all the electronics needed to enable the operator to know accurately how much manure he is spreading onto the land.

The Teagle Titan 10 Spreading Compost

The Teagle Titan 10 Spreading Compost

It is now 77 years since the company was formed and 83 years since Tom Teagle sold his first Tipcart. It would be a very brave person who tried to predict what the next 77 years of Teagle Machinery Ltd has in store. At the beginning of 2020, everything was running pretty much as normal, but 3 months later, the country and much of the world is locked down due to the coronavirus pandemic which is sweeping the globe. However, there is a big ‘But’, the world’s population will still need feeding and Teagle Machinery is a manufacturer of machines which help farmers to produce food. It will be interesting to look back in say 10 years’ time to see how the country and the world has climbed out of the situation that it is in now, together with where Teagle Machinery Ltd has fitted into the grand scheme of things.

Acknowledgements:

Many thanks to Fred Teagle and Tony Mansell whose book “Teagle, Reflections on 75+ years 1937 – 2015” has provided valuable background material for this article.

Cover Photo: The Blackwater factory in the 1970s

End notes:

- Silage is a fodder made from green foliage crops, preserved by acidification achieved through fermentation. It made during the spring/summer months and is conserved as a winter feed for cattle and sheep.

- Clamp silage is silage made in a clamp – a large enclosed area, usually, but not always, having a concrete floor and walls. The harvested crop is packed in tightly and sealed by a plastic sheet, weighted down by recycled tyres or sand bags.

Geoff Osborne grew up on a farm in West Penwith and, after graduating in Agricultural Engineering, joined Ford Tractors. After 8 years in Essex, the lure of Cornwall proved too great – he returned home to join Teagle’s in 1978 and has been a Director since 1995.

Geoff Osborne grew up on a farm in West Penwith and, after graduating in Agricultural Engineering, joined Ford Tractors. After 8 years in Essex, the lure of Cornwall proved too great – he returned home to join Teagle’s in 1978 and has been a Director since 1995.

Thoroughly enjoyed as usual!!